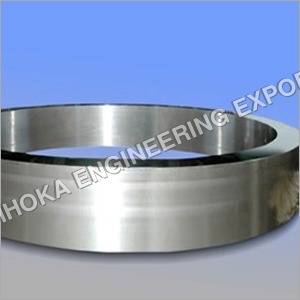

Tyres For Kilns and Ball Mill

MOQ : 10 Pieces

Tyres For Kilns and Ball Mill Specification

- Hardness

- 240-340 HB (Brinell Hardness)

- Vehicle Type

- Industrial rotary equipment

- Weight

- Can range from 1 ton to over 40 tons depending on size

- Application

- Rotary kilns and ball mills

- Valve Type

- N/A (solid forged steel construction, no valve)

- Load Capacity

- Heavy duty industrial grade, supports high axial and radial loads

- Size

- Custom engineered to client specification

- Tires & Tubes Type

- Kiln and Ball Mill Tyre / Riding Ring

- Tire Design

- Single piece hollow forged ring

- Usage

- Industrial (cement, mining, metallurgy kiln and mill machines)

- Diameter

- Up to 7 meters (customizable as per requirement)

- Width

- Up to 1.5 meters

- Section Width

- Customizable as per equipment specification

- Pattern Depth

- N/A (smooth design, no tread pattern)

- Car Make

- N/A (industrial rotary machinery only)

Tyres For Kilns and Ball Mill Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash Advance (CA)

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Tyres For Kilns and Ball Mill

We are a remarkable entity, engaged in offering a superior assortment of Tyres For Kilns and Ball Mill. These tyres find usage cement, metal casting, mining and dyeing industries. Additionally, Tyres For Kilns and Ball Mill can be availed in different specifications at most competitive price range to our clients. These are generally demanded for raising temperature of material in continuous process.

Engineered for Demanding Environments

Our kiln and ball mill tyres are specifically designed to endure extreme temperatures and heavy loading conditions common in cement, mining, and metallurgical applications. Manufactured through precision processes such as casting, forging, and heat treatment, they provide optimal hardness and enduring strength to support your rotary equipment in the most challenging environments.

Customization to Fit Your Needs

We recognize that every operation is unique. That's why we provide tailored solutions-customizing diameter, width, section profile, and material grade of tyres precisely to your drawing or equipment specification. Whether you require additional corrosion resistance or a specific surface finish, our manufacturing experts ensure the product matches your exact requirements.

Lasting Performance and Reliability

Each tyre undergoes meticulous machining or fine finishing, resulting in high dimensional accuracy and smooth shrink-fit installation over your kiln or ball mill shell. Their robust construction and engineered surface treatments combine to maximize service life, minimize maintenance, and guarantee consistent, reliable operation under heavy usage.

FAQ's of Tyres For Kilns and Ball Mill:

Q: How are kiln and ball mill tyres installed on rotary equipment?

A: The tyres are typically mounted using a shrink-fit method, where the tyre is heated, expanded, and then fitted over the shell of the kiln or ball mill. As it cools, the tyre contracts to form a precise, secure fit, ensuring reliable performance during operation.Q: What materials and surface treatments are used in the tyres' construction?

A: Our tyres are manufactured from high-quality cast steel or alloy steel. They can receive various surface treatments such as fine machining for dimensional accuracy or special coatings to enhance corrosion resistance, depending on your operation's requirements.Q: When should kiln and ball mill tyres be replaced?

A: Replacement is recommended when tyres show significant signs of wear, cracking, loss of dimensional accuracy, or when there is reduced performance affecting the rotary equipment's operation. Regular inspections help determine the ideal timing for replacement to avoid unexpected downtime.Q: Where are these tyres primarily used?

A: These tyres are designed for industrial rotary equipment, particularly in cement plants, mining operations, and metallurgical industries. They are integral components for rotary kilns and ball mills used in these environments.Q: What is the manufacturing process for these tyres?

A: The tyres are produced using precision casting or forging, followed by controlled heat treatment to achieve the desired hardness (240-340 HB). Final machining or fine finishing ensures tight tolerances and readiness for immediate installation.Q: How do customized tyres benefit my operations?

A: Customization ensures the tyre fits your equipment perfectly, accommodating unique requirements for diameter, width, section, alloy composition, and surface finish. This maximizes equipment life, optimizes performance, and reduces maintenance frequency.Q: What are the advantages of using your tyres compared to standard options?

A: Our tyres offer superior heat and corrosion resistance, high load-bearing capability, long operational life, and can be tailored to any specification. These factors collectively improve machine uptime and sustainability, making them a cost-effective investment for industrial rotary equipment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS